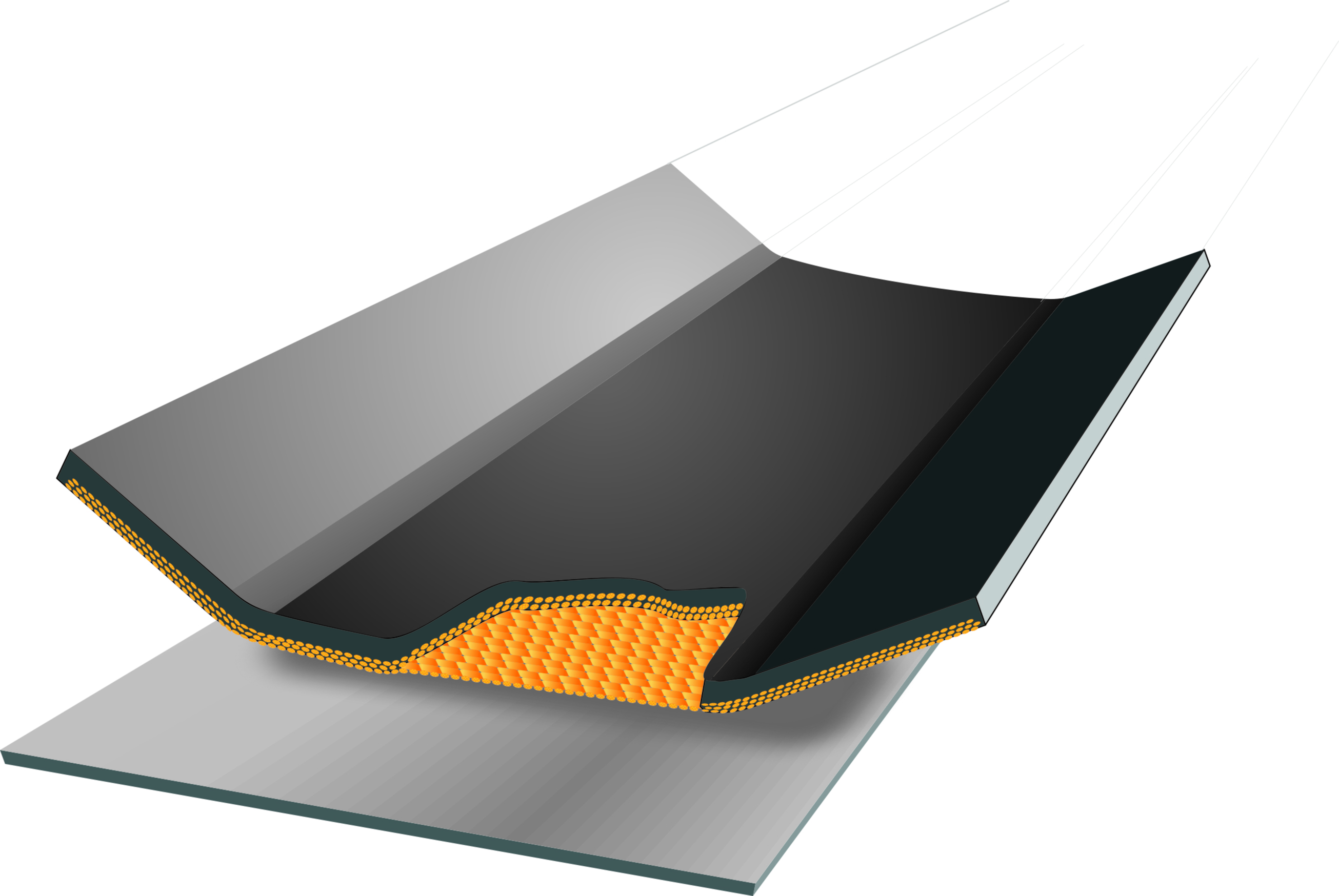

DBP WearTECH

The conveyor belt benchmark for wear-resistance

The combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are chosen to best suit the application in a range of cover types.

DBP covers are in a league of their own when it comes to matching the life to the application. The mechanism of wear to conveyor belts is highly complex. An infinite mix of product size, sharpness and shape that strikes the belt surface at many different velocities all play a role. Also affecting rate of wear are the operating conditions.

Developing belt conveyors that perform well in all these combinations can be a challenge without the huge database of knowledge gathered from continuous real time monitoring at a micro-level of the entire belt thickness profile. The BTM Belt Thickness Monitoring System designed by REMA TIP TOP TECHNOLOGIES system is the first conveyor belt monitoring system to continuously and automatically monitor the thickness of the belt. Data captured by numerous units installed around the world is being used to monitor the performance of rubber compound. This information has led to the development of belt cover rubber compounds that uniquely fit the application.

Specifications

| Cover | Abrasion < mm3 | Elongation at break min. in % |

Min. ambient temperature °C |

Constant material temperature in °C |

Max. temporary material temperature in °C |

Polymer basis |

| AA* | 130 | 400 | -30 | 80 | 90 | SBR |

| Y | 150 | 400 | -30 | 80 | 100 | SBR |

| X/H | 120 | 450 | -40 | 80 | 90 | NR |

| W/D | 90 | 400 | -30 | 80 | 90 | NR/SBR |

More products...

DBP WearTECH

The conveyor belt benchmark for wear-resistance The combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are…

Read more

DBP LavaTECH

Heat-resistant HR GRADE Our range of DBP LavaTECH is descriptive and includes the resistance to heat and heated material conveyed.…

Read more

DBP OilTECH

Oil-resistant G grade DBP OilTECH covers provide good tear, cut and abrasion resistance and also are resistant to swelling when…

Read more

DBP SlideTECH

DBP SlideTECH incorporates a special high density fabric weave preventing rubber striking through during vulcanization. There is no rubber on…

Read more