DBP FlexTECH

Textile straight-warp belts from 400 N/mm in 1 ply to 2500 N/mm in 2 plies

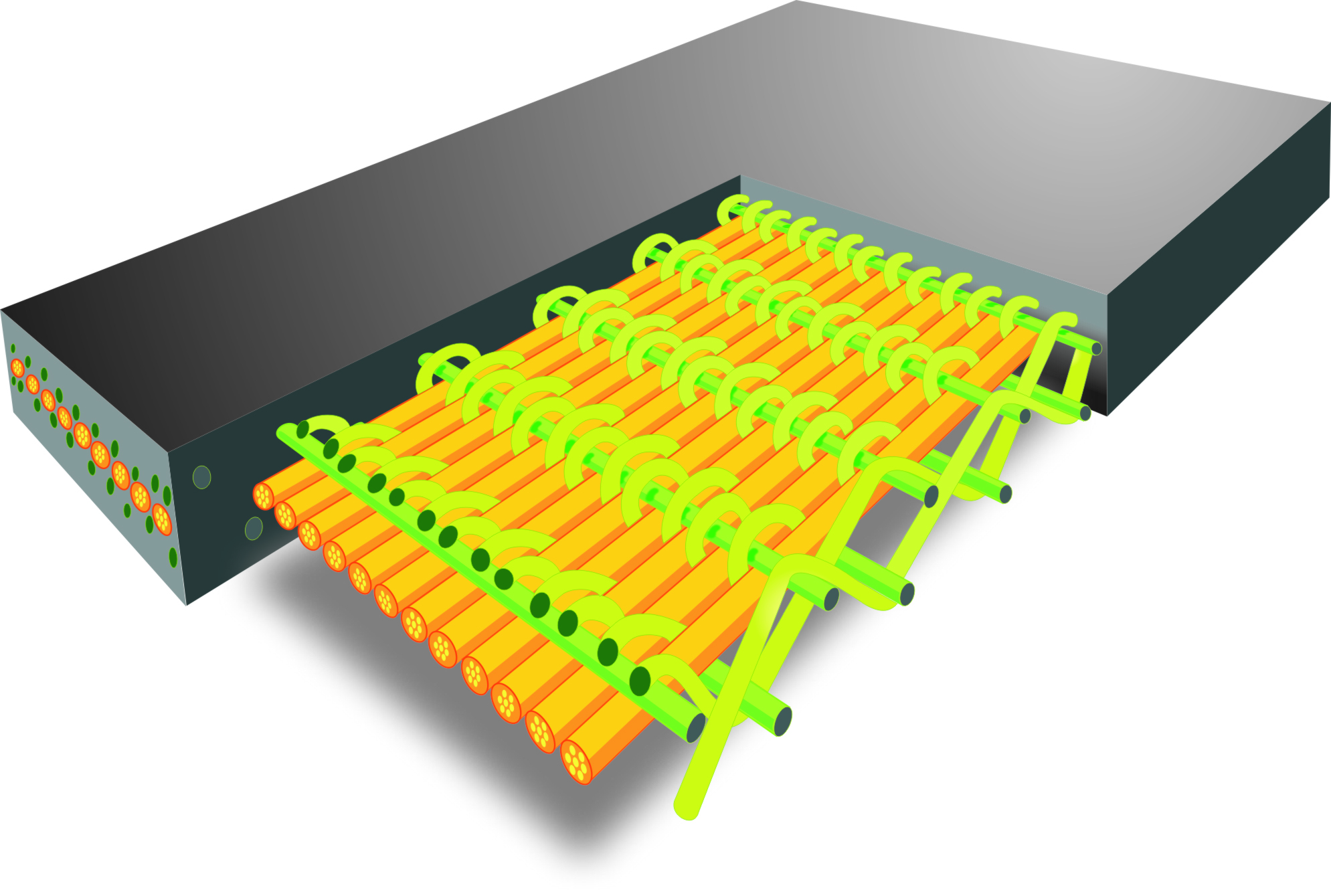

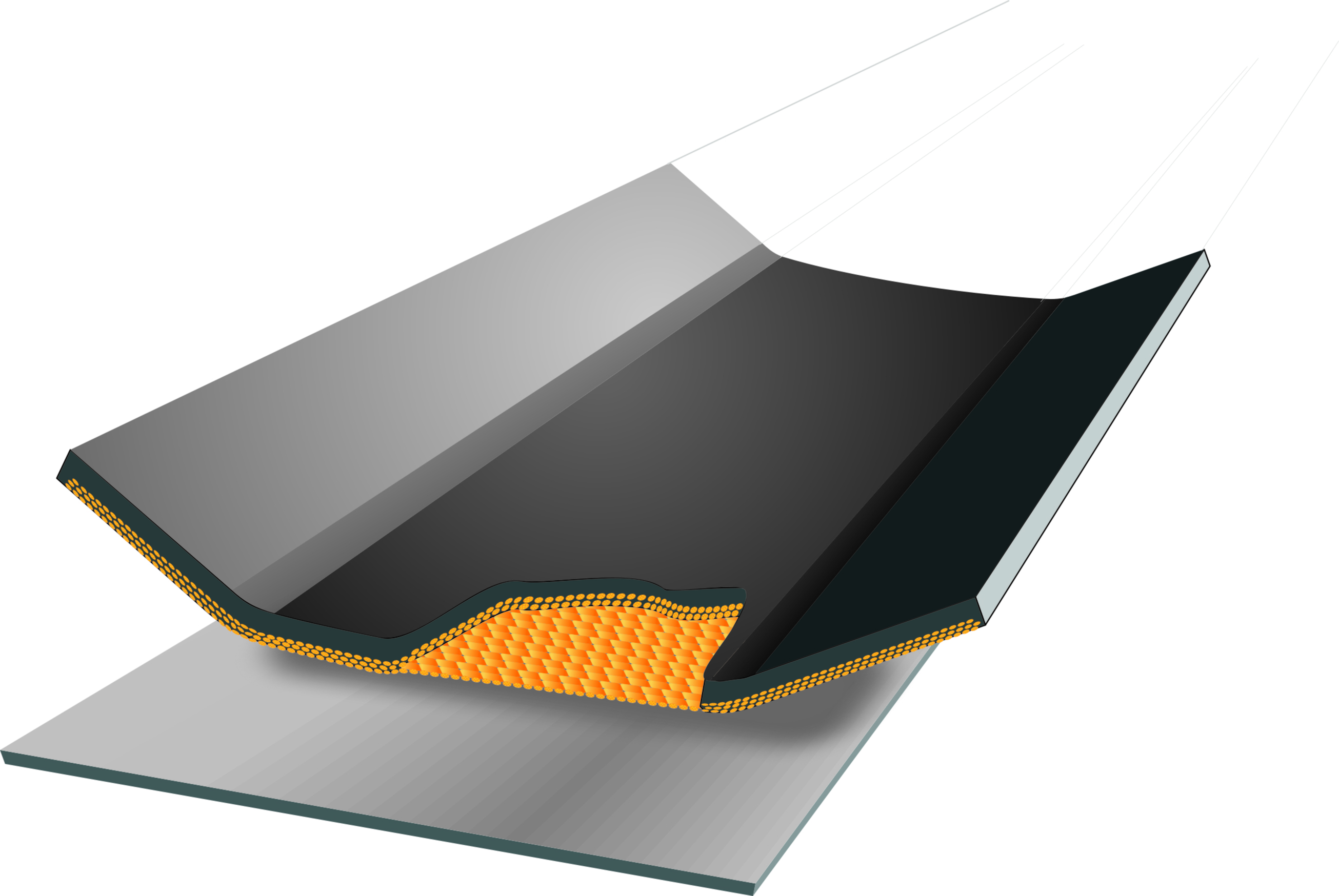

DBP FlexTECH is a polyester straight-warp belt composed of one or two plies protected on both top and bottom sides by weft lines in polyamide.

Due to the thin carcass, DBP FlexTECH can be used with smaller pulley diameters than textile plied or steelcord belts. Straight-warp conveyor belts are used on heavy duty conveyors where resistance to the effects of heavy impacts and resistance to tearing are important characteristics, typically seen in quarrying, open cast mining and steel industries or in applications where heavy-duty and yet narrow belts arerequired, such as in tunnelling. The carcass frame thus

constructed is adhered RFL and may be coated of different types of rubber cover, anti-abrasive ( X , Y, etc.), oil-resistant (G, G+), heat-resistant (T150°, T200°), etc.

Specifications

| Cover | Abrasion < mm3 | Elongation at break min. in % | Min. ambient temperature in °C | Constant material temperature in °C |

Max. temporary material temperature in °C |

Polymer basis |

| AA* | 130 | 400 | -30 | 80 | 90 | SBR |

| Y | 150 | 400 | -30 | 80 | 100 | SBR |

| X/H | 120 | 450 | -40 | 80 | 90 | NR |

| W/D | 90 | 400 | -30 | 80 | 90 | NR/SBR |

| T1 | 150 | 400 | -20 | 150 | 170 | SBR |

| T2 | 150 | 290 | -20 | 220 | 400 | EPDM |

| G | 150 | 350 | -20 | 80 | 90 | SBR/NBR |

| G+ | 140 | 350 | -20 | 80 | 90 | NBR |

| G1 | 170 | 450 | -20 | 80 | 90 | SBR/NBR |

| K/S | 200 | 350 | -20 | 80 | 90 | SBR |

| V/VT | 160 | 350 | -20 | 80 | 90 | CR |

More products...

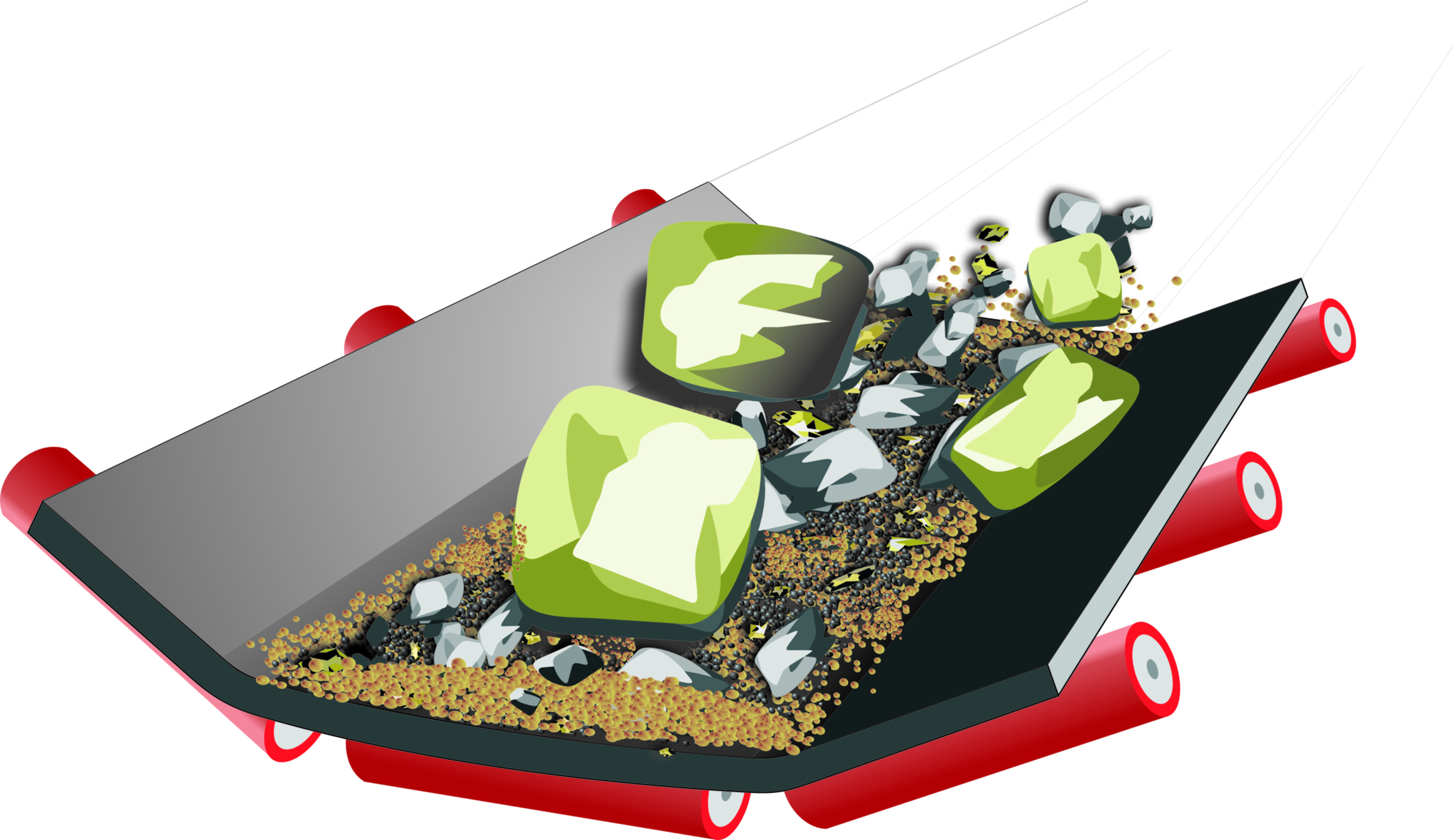

DBP WearTECH

The conveyor belt benchmark for wear-resistance The combination of tensile strength, abrasion resistance and elasticity of the conveyor cover are…

Read more

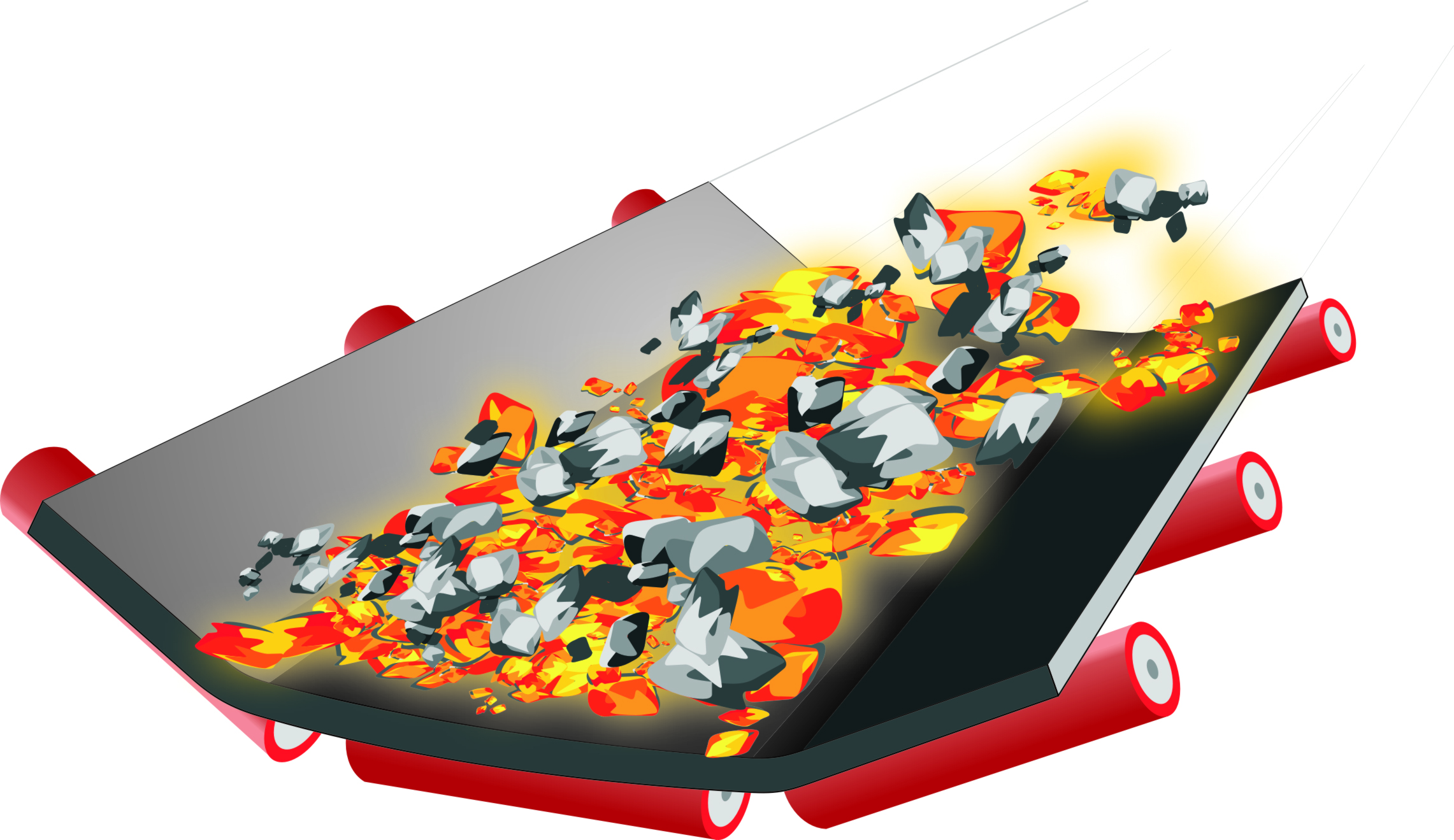

DBP LavaTECH

Heat-resistant HR GRADE Our range of DBP LavaTECH is descriptive and includes the resistance to heat and heated material conveyed.…

Read more

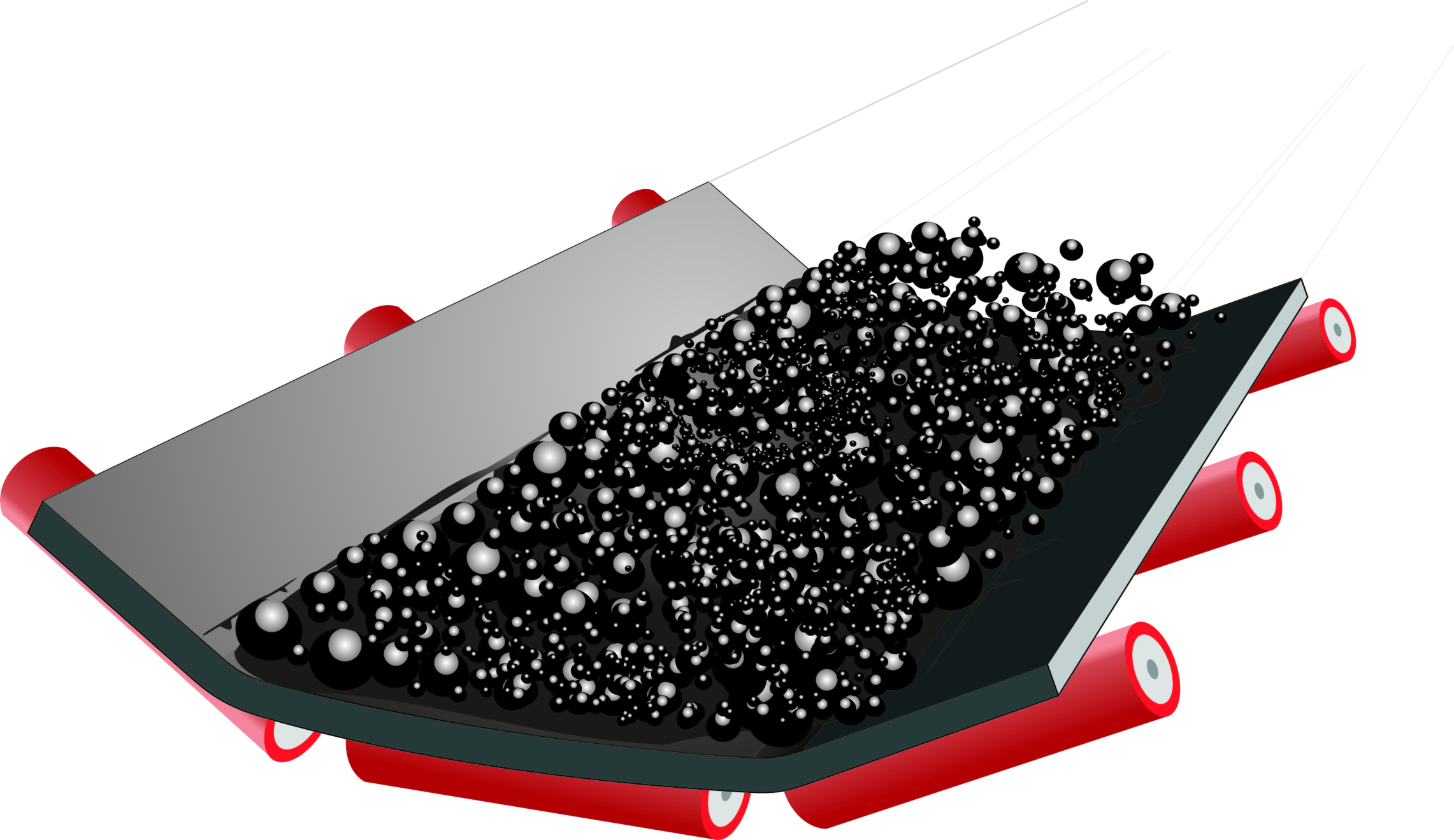

DBP OilTECH

Oil-resistant G grade DBP OilTECH covers provide good tear, cut and abrasion resistance and also are resistant to swelling when…

Read more

DBP SlideTECH

DBP SlideTECH incorporates a special high density fabric weave preventing rubber striking through during vulcanization. There is no rubber on…

Read more